Position:Home>>Copper tungsten

Email:ebiz@ctia.com.cn

Related Links

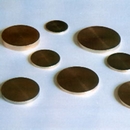

Copper tungsten

Copper tungsten

Copper tungsten Alloy (W-Cu) is the composite of tungsten and copper which own it excellent performance of tungsten and copper. It is used widely in such industries as engine, electric power, electron, metallurgy, spaceflight and aviation.

The manufacturing process is as follows: press the refractory metal, sinter the pressed compact at a high temperature, and infiltrate it with copper. All this is done under very closely controlled conditions. The result is a relatively hard material with superior arc and wear resistance, high physical Properties: at elevated temperatures, and good electrical and thermal conductivity.

Copper tungsten alloy product is a sintered copper-tungsten material manufactured by powder metallurgy. It forms dense composite offering hardness, wear resistance and a high softening temperature of tungsten combined with the good electrical conductivity of copper.

A combination of the advantages of tungsten and copper, high temperature resistance, electric arc ablation, high intensity, than the major, conductive, thermal conductivity, and ease of machining, and it has features such as cold sweating, as with tungsten high hardness, high melting point, anti-adhesion characteristics, often used to do a certain resistance to abrasion, resistant to high temperature welding, butt welding electrode.

1, Diameter: 1.5-100.0mm

2, Length: 50-1000mm

3, Density: 12.60-17.05 g/cm3

4, Composition: W 55-90%, Cu 10-45%

5, Surface: Sintering surface, Forged surface, Ground surface

2, Length: 50-1000mm

3, Density: 12.60-17.05 g/cm3

4, Composition: W 55-90%, Cu 10-45%

5, Surface: Sintering surface, Forged surface, Ground surface

1, width×Length: (2.0-100.0mm)×(2.0-100.0mm)

2, High: 50-1000mm

3, Density: 12.60-17.05 g/cm3

4, Composition: W 55-90%, Cu 10-45%

5, Surface: Sintering surface, Forged surface, Ground surface

2, High: 50-1000mm

3, Density: 12.60-17.05 g/cm3

4, Composition: W 55-90%, Cu 10-45%

5, Surface: Sintering surface, Forged surface, Ground surface

1, Main grades: CuW50, CuW55, CuW60, CuW65, CuW70, CuW85

2, Length: 5mm-200mm

3, Width: 5mm-200mm

4, Thickness: 0.1mm-5.0mm

5, Semi-finished or finished (Ni/Au plated) products available

2, Length: 5mm-200mm

3, Width: 5mm-200mm

4, Thickness: 0.1mm-5.0mm

5, Semi-finished or finished (Ni/Au plated) products available

1, Grade: Mo85Cu15, Mo70Cu30, Mo60Cu40, Mo50Cu50

2, Length: 5mm-300mm

3, Width: 5mm-300mm

4, Thickness: 0.1mm-5.0mm

5, Semi-finished or finished (Ni/Au plated) products available

2, Length: 5mm-300mm

3, Width: 5mm-300mm

4, Thickness: 0.1mm-5.0mm

5, Semi-finished or finished (Ni/Au plated) products available

Tungsten copper heat sink is a composite of tungsten and copper. The coefficient of thermal expansion (CTE) of the composite can be designed by controlling the content of tungsten, matching that of the materials, such as Ceramics (Al2O3, BeO), Semiconductors (Si), Metals (Kovar), etc. The products are widely application in the fields such as radio frequency, microwave, high power diode packaging and optical communication system.

Copper molybdenum high performance composites are fabricated from carefully controlled porous Molybdenum that is vacuum infiltrated with molten copper. This results in a MoCu composite that has high conductivity and a matched low thermal expansion for heat sinks.

The high Electrical & thermal conductivity of copper are combined with the arc-resistant & non-welding properties of tungsten or their carbides to form an extensive series of compositions each designed to give the best performance for your particular application.

1, Tungsten copper Alloy (WCu)

2, Class: Round tube and Square tube

3, OD: 3.0mm to 380 mm;

4, Length: max 1000 mm;

5, Wall thickness: min 0.3 mm

All can be produced as the requirements of customers.

2, Class: Round tube and Square tube

3, OD: 3.0mm to 380 mm;

4, Length: max 1000 mm;

5, Wall thickness: min 0.3 mm

All can be produced as the requirements of customers.